How to choose a supercharging pile cooling pump?

- Classification: ARTICLES

- Release time:2023-01-15 06:48

- Visits:278

How to choose a supercharging pile cooling pump?

- [Summary description] ARTICLES

- Release time:2023-01-15 06:48

- Visits:278

With the implementation of China’s green development concept and the deployment of new energy strategies, the number of new energy electric vehicles continues to climb, and the supporting electric vehicle charging and replacement facilities have also begun to grow significantly. As a new trend in promoting people’s green travel, the development of supercharging pile systems has gradually become a major technical problem in development. The biggest advantage of supercharging piles over household power sources is that they can provide sufficient electric energy for new energy vehicles in a short period of time, reducing charging time from several hours to tens of hours to several minutes to tens of minutes. The significant reduction in charging time will greatly facilitate people’s travel and better meet their travel needs.

The principle of ‘fast charging’ for supercharging piles is to increase the instantaneous power to achieve an increase in current delivery while maintaining the rated voltage unchanged, thereby greatly reducing charging time. However, as the current increases, so does the heat generated by system equipment. These high-density heat will accelerate the aging of charging pile equipment. If not dissipated in time, overheated supercharging piles can also cause serious safety accidents. To solve the heating problem, the quickest way is to thicken the connecting cable to reduce heat generation, but this also means that as the weight of the charging cable increases, people will be troubled by its weight during self-service charging. The cooling methods that can be applied to charging systems can be divided into natural cooling, forced air cooling and liquid cooling.

Natural cooling: that is, without special equipment, reduce equipment temperature through natural air circulation. This method is most cost-effective but also has lowest efficiency. Forced air cooling: that is installing fan radiators inside equipment and using forced convection for heat dissipation with air as exchange medium. Forced air cooling can take away large amounts of heat but also occupies large space; during wind cooling process it may bring new problems such as dust moisture corrosive gases etc. Liquid cooling: that is wrapping a layer of radiator on charging cable running pump circulating coolant inside radiator band. Liquid cooling method allows coolant recycling closed heat dissipation environment ensures heat dissipation efficiency while ensuring cleanliness during process.

Supercharging piles belong to working conditions with small heat dissipation space and extremely high heat density. Liquid cooling technology can be applied where forced convection and phase change systems cannot achieve heat dissipation effect or where thermal energy density is extremely high. Therefore using liquid cooling technology is most efficient way save space reduce system weight.

So how do you choose ‘heart’ liquid-cooled link - supercharging pile liquid-cooled pump? To choose suitable supercharging pile liquid-cooled pump first understand applicable requirements for working conditions supercharging pile system. Supercharging piles usually installed residential areas business districts units parking lots other places where people frequent daily activities traffic demand large flow So when choosing supercharged pile liquid-cooled pump should choose low noise small size no leakage high reliability small flow high pressure long service life micro-pump There many micro-pumps meet these requirements how determine which type micro-pump meets requirements?

First, we need to determine the performance parameters of the supercharging pile liquid cooling pump. Supercharging piles need to be installed in residential areas and commercial districts, and strict control is required for the overall noise level and space occupied by the equipment.

According to design standards, the noise of the coolant delivery pump should be below 60dB and its size should be compact. Currently, systems using ethylene glycol or silicone oil as cooling media have a flow rate design range of 2-5 liters/minute and a delivery pressure within 6Bar.

Based on these parameter requirements, we can narrow down our selection range between gear pumps and vane pumps.

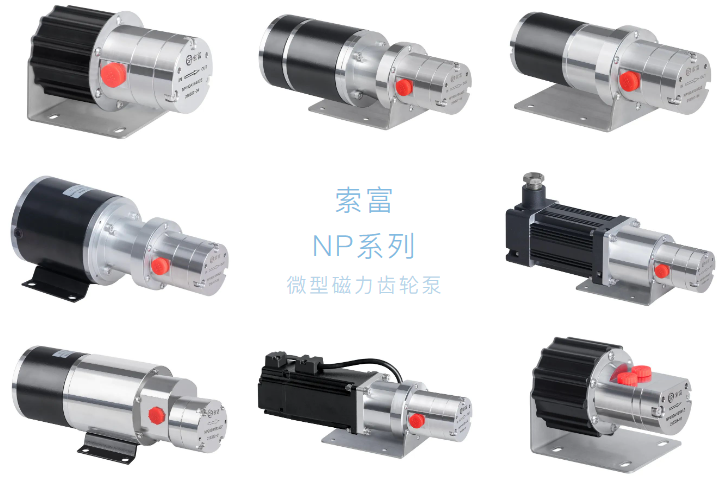

Suofu NP series micro-magnetic gear pump as a volumetric pump can still have good boosting effect in gas-liquid two-phase state. It has small size, light weight, good reliability, low wear rate, long service life, static sealing without leakage. It also has long dry running ability and self-priming ability. The noise is low and it can transport a wide range of medium viscosity. However in terms of price gear pump parts are all precision machined so their price will be higher than vane pumps.

Vane pumps are also a type of volumetric pump with compact structure and high efficiency. They have strong self-priming force suitable for transporting light oil and viscous oil with low noise and lower price. However during use vanes wear out severely producing large amounts of fine wear particles causing blockage which affects both pump performance and system heat exchange efficiency.

In summary excluding price factors gear pumps are more suitable than vane pumps as coolant delivery pumps for supercharging piles in terms of performance.

When choosing a suitable gear pump as a supercharging pile liquid cooling pump, we should not only consider the price, but also comprehensively consider the technology, performance and after-sales service of the pump.

Technology determines quality. Therefore, technology and quality are the core competitiveness of a brand. When it is difficult to choose a supercharging pile liquid cooling pump, you can choose a brand with strong technical strength.

Choose a brand and comprehensively consider from three aspects: project experience, R&D capability and technical team of supercharging pile liquid cooling pump manufacturers.

In terms of project experience, you can find suitable supercharging pile liquid cooling pumps by comparing the performance characteristics of existing system equipment advertised by major research institutes and well-known enterprises on the market.

For example, Suofu’s NP series supercharging pile liquid cooling pumps are designated suppliers for 7 institutes of the Chinese Academy of Sciences, major domestic and foreign universities and well-known enterprises. The products are also used in military industry, nuclear power, chips, deep-sea robots , magnetic levitation compressor units , lithium batteries , fuel cells , offshore wind power systems , CRs and other occasions with high stability requirements .

As a mature product with sufficient market application cases , NP series supercharging pile liquid cooling pumps can save a lot of time for comparison testing .

According to the industry application performance and technical requirements of high-power charging piles , Suofu has specially developed and customized NP190 equipped with 24V150W DC brushless motor for the new energy charging pile industry . The supercharging pile liquid cooling pump has been used in batches in the new energy charging pile market for more than 2 years and has been recognized by many well-known enterprises .

When developing high-power charging piles and purchasing super charging pile liquid cooling pumps, due to lack of understanding of the pump, it is also necessary to communicate with the manufacturer on technical requirements in advance. Manufacturers with independent technology development capabilities can provide detailed improvement and improvement suggestions for system problems through technical exchanges before procurement.

Similarly, manufacturers that have already put a large number of super charging pile liquid cooling pump products on the market can also provide solutions to some common technical problems in high-power charging pile systems based on various data and experience.

In terms of selecting product technical performance, it can also be considered from the manufacturer’s independent research and development capabilities.

Liquid cooling pump manufacturers with independent technology development capabilities can customize liquid cooling pumps according to customer system requirements when standard products do not fully meet customer design standards. Manufacturers with patented technology and technical teams have special customization capabilities.

Shanghai Suofu has 27 patented technologies (3 invention patents, 17 utility model patents and 7 design patents), including processing methods for cooling pumps, key component profile design, special material applications, overall appearance design and more. The technical team can develop and customize products according to customer needs and provide pre-sales technical support to help select models. In after-sales service, they can also provide good maintenance conditions.

During the purchase process, it is most important to determine whether the performance of the charging pile cooling pump meets the usage standards required by the configured equipment. Factors such as flow rate, pressure, viscosity, temperature resistance, wear resistance and service life are all important factors to consider during purchase.

Suofu NP190 magnetic gear pump equipped with a 24V150W DC brushless motor has a service life of more than 30,000 hours. The working temperature range is -45~60℃ and the liquid temperature range is -45~85℃. The flow rate is 1-5.5 liters/minute and outlet pressure is 0-7Bar.

The motor protection level provides IP55 and IP68 options. The motor can accept two speed control signals: 0-5V voltage signal or PWM signal. It can be controlled in forward or reverse rotation with multiple protection modes such as 150W limited power operation protection mode , controller overtemperature protection at 125℃ , stall protection mode etc.

In addition ,the interface position of Suofu NP190 supercharged liquid-cooled water pump body can be customized according to system layout requirements such as side inlet/outlet or top inlet/side outlet etc.

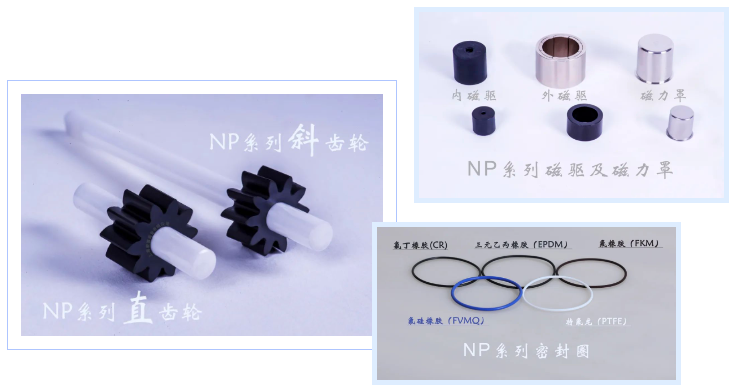

The pump body material of the NP series high-power charging pile liquid cooling pump is 316L. The core parts of the pump, gears and bearings, use Wiggs WG series high-performance special-filled PEEK engineering plastics. The gear shaft is made of high-precision industrial zirconia ceramics. The product has unique advantages in hardness, high and low temperature resistance, wear resistance, corrosion resistance and service life.

The delivery time of high-power charging pile heat dissipation pump products, pre-sales technical consultation and after-sales technical support are also important conditions for selecting a cooling pump. Suofu’s NP series high-power charging pile liquid-cooled heat dissipation pump technical team and production factory are both in China. They can provide customers with detailed system configuration and control matching consultation before sales and provide timely delivery time and convenient after-sales support. From pre-sale customization to connection installation to maintenance and repair, there are professional personnel tracking services.

-

-

- 客服联系方式

服务时间:9:00 — 18:00

24小时售后

Contact

-

Mr Lin:TEL(wechat):+86 13764319509

mail:lqx@s-fluid.com

whatsapp:966578718101

R & D sales: Room 602, 18 Feet Building, No. 597, Langao Road, Putuo District, Shanghai Production base: Building 10, Sanming Zhongguancun Science Park, No. 9, Yingbin Avenue, Qiujiang street