Why gear pumps are not suitable for transporting media with particles

- Classification: ARTICLES

- Release time:2023-01-15 06:48

- Visits:219

Why gear pumps are not suitable for transporting media with particles

- [Summary description] ARTICLES

- Release time:2023-01-15 06:48

- Visits:219

Author: Lin Qiangxing, Shanghai Sofu Industrial Co., Ltd.

Original link: Why gear pumps are not suitable for transporting media with particles

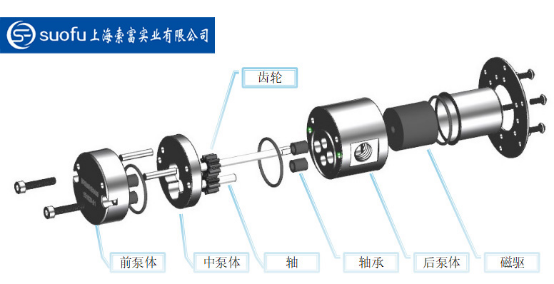

Gear pump is a type of positive displacement pump that relies on the volume change generated by the meshing process of a pair of gears to suck in and discharge liquid. The gears need to rotate, which means that there is a gap between the gears and the corresponding cavity.

It is precisely because of these gaps that there will always be some liquid returning from the high-pressure outlet area to the low-pressure inlet area during the operation of the gear pump. This is called internal leakage. In order to reduce internal leakage, the gap between gears and cavity is very small. Generally speaking, the lower viscosity of transported liquid and larger pressure difference between inlet and outlet means smaller gap.

Our company’s NP series micro gear pump can reach 20Bar (2MPa) differential pressure when transporting low viscosity liquids (such as water or other solvents), and minimum gap inside pump is controlled at about 0.02mm. This means that particles larger than this size will cause pump to jam.

In addition gears mesh with each other during operation meaning tooth surfaces contact each other and there is also frictional movement between bearings and shafts. If particles enter these parts they will cause serious wear reducing pump life.

-

-

- 客服联系方式

服务时间:9:00 — 18:00

24小时售后

Contact

-

Mr Lin:TEL(wechat):+86 13764319509

mail:lqx@s-fluid.com

whatsapp:966578718101

R & D sales: Room 602, 18 Feet Building, No. 597, Langao Road, Putuo District, Shanghai Production base: Building 10, Sanming Zhongguancun Science Park, No. 9, Yingbin Avenue, Qiujiang street