Selection of pipe diameter for micro gear pump system

- Classification: ARTICLES

- Release time:2023-01-15 06:48

- Visits:349

Selection of pipe diameter for micro gear pump system

- [Summary description] ARTICLES

- Release time:2023-01-15 06:48

- Visits:349

Author: Lin Qiangxing, Shanghai Suofu Industrial Co., Ltd.

Sometimes customers say that the flow rate of the pump does not meet the requirements.

At this time I will ask him a question: How large is the inner diameter of your inlet pipe and how long is it?

Generally users when designing large systems, Pay attention to the selection of pipe diameter, but it is easy to neglect when it comes to micro pump systems. At the same time for large industrial flow The selection of pipe diameters for systems has some clear specifications in some manuals. As long as you know the flow rate, temperature and viscosity, It is relatively easy to choose a suitable pipe diameter. But these manuals generally have a minimum pipe diameter down to DN25 and no further subdivision So how do you choose a suitable pipe diameter for applications with flow rates ranging from tens of milliliters per minute to tens of liters?

Here we are Do a simple discussion:

If purely considering the flow velocity of liquid:

1. Outlet pipe diameter (inner diameter):

For pump The outlet pipe diameter mainly considers two points:

1. The pipe diameter should not be too small and the flow rate should not be too fast to avoid unnecessary flow resistance loss.

2. The pipe diameter does not need to be too large to avoid unnecessary pipeline costs. We recommend that for liquids with about 1cp, The reasonable flow rate is between 1-3m/s. For example, for a flow rate of 5 liters/minute, the choice of inner diameter can be between 6mm (3m/s) ~10mm (1m/s). If viscosity increases, speed can decrease accordingly. The choice of outlet pipe diameter still depends on whether liquid resistance in pipes is appropriate. In cases where pipes are long and bends are many, increase the size appropriately; otherwise reduce it. Of course if outlet Pipe diameters decrease and outlet pressure will increase; money saved on pipes will be spent on increased costs for purchasing high-pressure pumps and increased power consumption during operation. Because pump power consumption W is proportional to product Q and pressure P.

2. Inlet pipe diameter (inner diameter):

In most cases (when there is no pressure at the inlet), the inlet of the pump can only rely on atmospheric pressure to suck in liquid. The maximum differential pressure from the inlet pipe end to the pump inlet end = 101kPa-NPSHr-height difference between liquid level and pump (assuming liquid tank is constant pressure). That is to say, the inlet conditions of the pump are far inferior to the outlet conditions because the maximum theoretical differential pressure is only one atmospheric pressure. Therefore, we recommend that for liquids with a viscosity of about 1cp, a reasonable flow rate in the inlet pipeline is 0.5-1.5m/s. For example, for a flow rate of 5 liters/minute, the choice of inner diameter of pipeline can be between 8mm(1.5m/s) and 14mm(0.5m/s). If viscosity increases, flow rate can decrease accordingly.

If transporting volatile liquids:

If transporting liquids that are easy to volatilize such as Freon. If inlet pipe is too small it may cause some degree of vacuum in pump inlet pipe which intensifies liquid gasification and ultimately may cause system to not work properly. At this time it is necessary to appropriately increase inner diameter of pipeline and bring pump as close as possible to liquid tank while reducing bends changes in diameter and valves on pipeline. It’s best to install vacuum gauge on pipeline so that vacuum degree inside pipeline can be monitored in real time reducing gasification phenomenon.

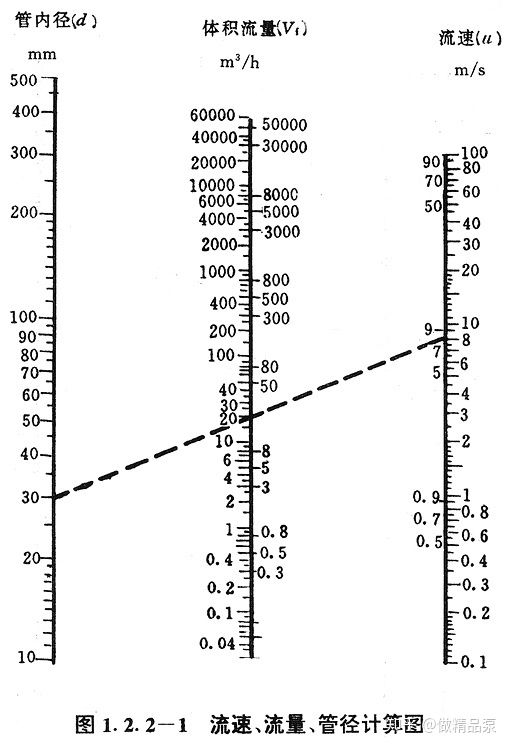

Here’s a chart for selecting pipelines mainly considering outlet:

So some friends may have the following questions: Is it better for the inlet pipe to be larger? In cases where pump self-priming is required, is it better for pump speed to be higher or lower? I will explain these questions in future articles.

-

-

- 客服联系方式

服务时间:9:00 — 18:00

24小时售后

Contact

-

Mr Lin:TEL(wechat):+86 13764319509

mail:lqx@s-fluid.com

whatsapp:966578718101

R & D sales: Room 602, 18 Feet Building, No. 597, Langao Road, Putuo District, Shanghai Production base: Building 10, Sanming Zhongguancun Science Park, No. 9, Yingbin Avenue, Qiujiang street