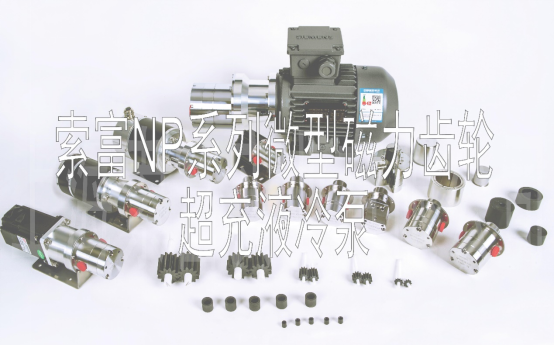

The application of Suofu NP series liquid-cooled gear pumps in the liquid cooling system of super charging pile guns

- Classification: ARTICLES

- Release time:2023-01-15 06:48

- Visits:248

The application of Suofu NP series liquid-cooled gear pumps in the liquid cooling system of super charging pile guns

- [Summary description] ARTICLES

- Release time:2023-01-15 06:48

- Visits:248

With the gradual popularization of new energy vehicles, the anxiety about the endurance and charging time of pure electric vehicles has become a common concern for car owners and car companies. In this context, the concept of super charging piles frequently appears in public view. Due to low charging power and small charging current, ordinary air cooling systems are sufficient to meet cooling requirements for old-fashioned charging piles. However, as the market’s demand for charging time becomes higher and higher, DC high-voltage 350KW or more supercharging systems have gradually emerged in the market.

In such high-power charging pile systems, the current of the charging gun is large and generates a lot of heat. However, due to weight restrictions, it is impossible to make the charging gun cable too thick. Therefore a liquid cooling system was born. At present there are two types of coolant used in liquid cooling systems for charging guns: antifreeze (ethylene glycol aqueous solution) and silicone oil. Below we discuss Suofu NP series micro-magnetic gear pump applications and their advantages and disadvantages compared to other types of pumps for these two commonly used media.

Suofu NP series product performance characteristics in typical 3KW liquid cooling system for supercharging station guns:

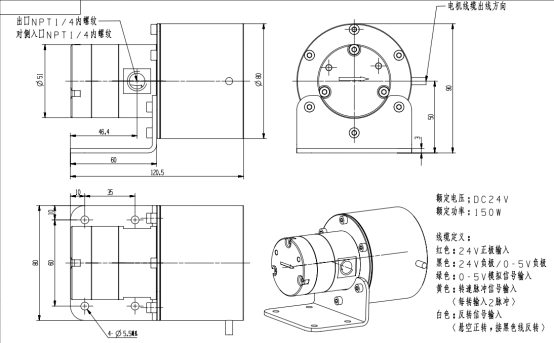

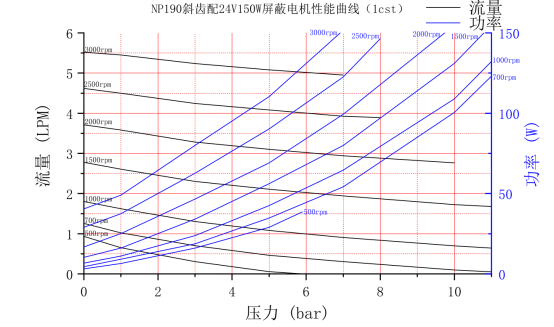

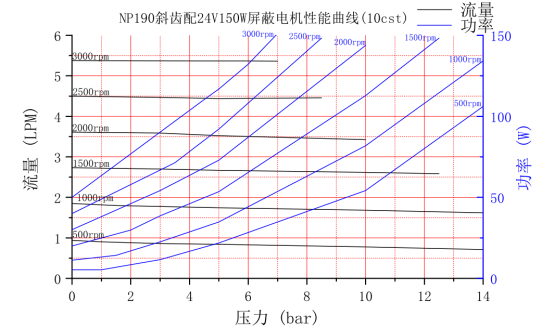

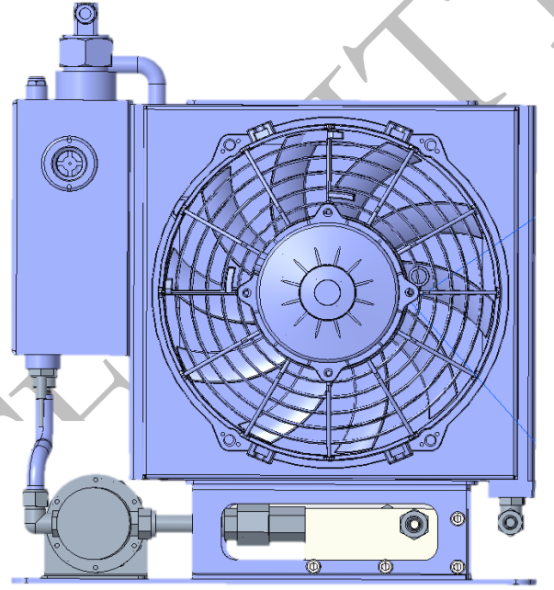

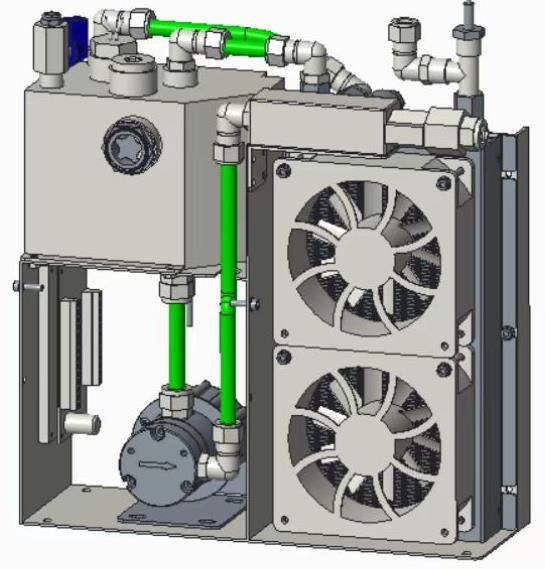

1. Shielded structure with small size. Suofu Industry’s specially customized NP190 shielded DC brushless motor-driven gear pump for supercharging station industry has a total length of only 120mm including pump body containing motor and built-in motor driver which can provide up to 8bar differential pressure at 5 liters/minute. The compact overall shape combined with ample flow pressure performance can help keep the overall volume of liquid cooling system to a minimum while having sufficient flow and pressure margin.

2. Wide range viscosity adaptability. Suofu NP series micro-magnetic gear pumps can be used to transport various media with viscosity ranging from 0.2~20000cps. Due to wide range applicability of charging piles temperature differences at installation locations as well as temperature differences between oil products during working/non-working states oil viscosity can vary from several centipoise to tens thousands centipoise within this range Suofu micro-gear pumps are well compatible.

3. High differential pressure with little influence on pump flow due to pressure fluctuations.

Whether transporting silicone oil with certain viscosity or low-viscosity ethylene glycol solution or fluorine-containing liquid Suofu pump can provide up to 20bar differential pressure actual working differential pressure also subject power limitation matching motor In low-pressure systems some customers also use lower-cost centrifugal pumps as liquid-cooling pumps but general centrifugal pumps have difficulty achieving 2-5bar differential pressure at flow rates between 2-5 liters/minute Additionally even under stable speed conditions centrifugal pump flow changes caused by pressure fluctuations much larger than gear pumps In other words gear pumps have certain flow metering function but centrifugal pumps can not .

4. Pump adapts long-term continuous operation under high-low temperature environments

DC brushless motors used by Suofu micro-magnetic gear pumps can work continuously long-term under environmental temperatures between -40°C-70°C while pump head itself can work continuously long-term within range -120°C-150°C We use high-grade rare earth magnets resistant high temperatures ensure magnetic field torque remains stable throughout entire life cycle under high-low temperature environments

5. Motor comes with overtemperature protection overcurrent protection functions Among them overcurrent protection function has two protection modes: overcurrent shutdown protection overcurrent non-stop constant power operation

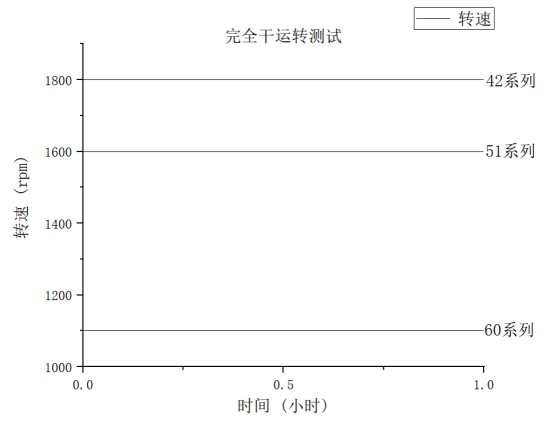

6.Pump has excellent self-priming ability can run dry continuously long time Pump’s excellent self-priming ability allows customers easily use pump add fluid before starting up When designing NP series micro-magnetic gear pumps materials selected tooth profile processing technology were repeatedly tested therefore entire NP series products can run dry without any additional wear at relatively high speeds up one hour To ensure product reliability all Suofu NP series products undergo testing under completely dry running conditions maximum operating speed As one model within 51 series NP190 allows long-time dry running at speed 1600rpm.

7. Magnetic drive no leakage risk

Suofu micro-pumps adopt magnetic coupling form whole pump without dynamic seal very suitable maintenance-free use environment

8.Flexible pump interface configuration NP190 interface Suofu micro-pump can flexibly configured according customer’s system We have standard left-in-right-out interface also provide top-in-side-out interface adapt different system structures .

9. Low wear and long life.

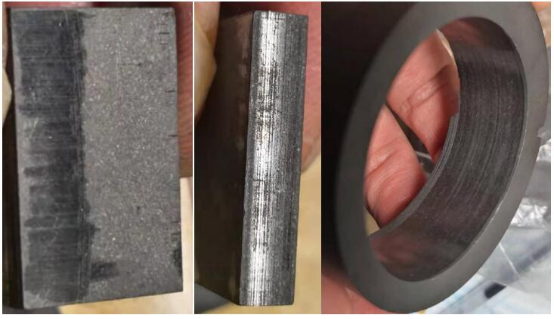

Due to the use of very advanced wear-resistant materials and specially designed gear profiles, Suofu gear pumps have lower wear and longer life than vane pumps and similar gear pumps. Suofu gear pump has a low-slip gear profile patent, which greatly reduces sliding friction during operation compared to ordinary gear profiles. Especially compared to vane pumps (also known as rotary vane pumps), Suofu’s gears do not touch the pump body at the top of the teeth during operation, and the sliding friction of moving parts during operation is reduced by multiples. Vane pumps not only have full-area friction between the two sides of the vane in the slot during operation, but also full-time friction between the top of the vane and the pump body. In addition, since most vanes on this type of vane pump on the market are made of carbon graphite, it is very easy to wear out a large amount of graphite into the back-end system pipeline during operation, reducing system performance. Below are several photos showing wear on vanes and eccentric rings from an imported brand vane pump after working for 10 hours at 8 bar pressure in pure water.

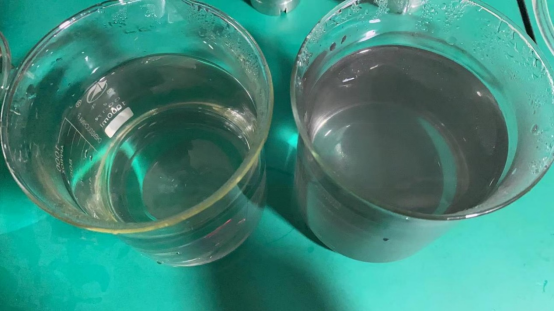

The comparison photo after experiment shows that due to graphite powder falling off from vane pump causes clear water to turn black. On left side is our gear pump’s liquid while on right side is liquid from a vane pump.

The NP series micro-pump products can provide dry installation or submerged installation according to different customer needs; they can be equipped with DC brushless motors, AC variable frequency motors or servo motors; The structure form can be customized; It can meet different system requirements for product structure size, inlet/outlet orientation, power supply form and control mode.

In actual use in systems, magnetic gear pumps need to ensure cleanliness of transported liquids; it is recommended that filters with no less than 400 mesh be installed at inlet with nominal flow rate greater than 1.5-2 times that of pump flow rate.

-

-

- 客服联系方式

服务时间:9:00 — 18:00

24小时售后

Contact

-

Mr Lin:TEL(wechat):+86 13764319509

mail:lqx@s-fluid.com

whatsapp:966578718101

R & D sales: Room 602, 18 Feet Building, No. 597, Langao Road, Putuo District, Shanghai Production base: Building 10, Sanming Zhongguancun Science Park, No. 9, Yingbin Avenue, Qiujiang street